How to Choose the Right Design for a Designed Experiment (DOE)?

The choice of an experimental design depends on the goals and objectives of the experiment and the number of factors to be investigated. The type of design is chosen according to the experimental objectives they meet.

Why is Design of Experiments ( DoE ) so Important?

The significance of Designed Experiments ( Design of Experiments, DoE) cannot be overstated, especially in today’s data-driven and highly competitive world. They serve several crucial purposes, starting with the ability to systematically and efficiently explore multiple factors and their interactions.

In product development and process optimization, this means identifying the optimal settings or conditions that result in the desired outcomes.

Furthermore, DOE helps in minimising waste, conserving resources, and reducing the costs associated with experimentation. It aids in robust decision-making, ensuring that the conclusions drawn from experiments are reliable and reproducible.

Factors Influencing Experimental Design Selection

- Experiment Objectives

The first critical step in choosing the right experimental design is a clear definition of the experiment’s objectives. Are you aiming to optimise a manufacturing process for maximum output, understand the impact of various factors on a biological system, or simply explore how different variables interact with one another?

Your objectives shape the entire experimental design process, guiding you towards the appropriate choice. For instance, if your goal is to identify the key factors influencing a specific outcome, you might lean towards a factorial design that systematically tests each factor’s impact. On the other hand, if you seek to uncover complex interactions, response surface methodology (RSM) might be the preferred option.

- Number of Factors

The number of factors to be investigated plays a pivotal role in experimental design selection. In situations where numerous factors are in play, a full factorial design—a method that examines all possible combinations of factors and levels—may become impractical due to resource and time constraints. Here, fractional factorial designs come into play, allowing researchers to explore a subset of factor combinations while still extracting valuable insights. It’s essential to strike a balance between comprehensiveness and feasibility.

Additionally, researchers must consider factors that might not be under their control but can influence the outcomes, such as external environmental conditions, to ensure their experimental design accounts for potential sources of variation.

- Resource Constraints

Real-world experiments often operate within budgetary, temporal, and resource constraints. While the ideal experimental design might be to explore all possible scenarios exhaustively, this is not always feasible.

Therefore, researchers must be pragmatic in their approach, taking into account the limitations imposed by available resources. This might entail selecting an efficient design that provides sufficient information while conserving resources or conducting experiments in stages, progressively building upon previous results.

Budgeting for pilot testing and robust data analysis tools is also vital, as they contribute to the overall success of the experimental endeavour, ensuring that the data collected can be effectively leveraged to meet the objectives within the resource constraints.

Common Types of Experimental Designs

Experimental designs are versatile tools that cater to a wide range of research needs. Here are some of the most common types:

1. Full Factorial Design

A full factorial design is a comprehensive approach that involves testing all possible combinations of factors and their respective levels. While this design provides a thorough understanding of how each factor and their interactions affect outcomes, it can be resource-intensive, especially when dealing with numerous factors and levels. Researchers often employ full factorial designs when they need exhaustive data for in-depth analysis and optimization.

2. Fractional Factorial Design

Fractional factorial designs are a more efficient alternative to full factorial designs, particularly when faced with resource limitations. Instead of examining every possible combination, fractional factorial designs select a subset of factor combinations to investigate. This approach reduces the number of experiments required while still providing valuable insights into which factors have the most significant impact on the outcomes. Fractional factorial designs are widely used when researchers seek to balance data quality with resource constraints.

3. Taguchi Method

The Taguchi method, developed by Japanese engineer and statistician Genichi Taguchi, focuses on optimising processes while considering robustness to variations. It is particularly useful in manufacturing settings where process stability and product quality are essential. The Taguchi method emphasises the identification of optimal factor settings that minimise sensitivity to external influences or “noise.” This technique has been instrumental in improving product and process quality in industries such as automotive manufacturing and electronics.

4. Response Surface Methodology (RSM)

RSM is a powerful tool for optimising processes and products when multiple factors influence the response variable. This design explores the relationships between factors and the response variable while accounting for interactions. Researchers use mathematical models derived from RSM to predict optimal factor settings that maximise or minimise the response variable. RSM is widely employed in fields like chemistry, engineering, and pharmaceuticals to fine-tune processes and achieve desired outcomes efficiently.

Step-by-Step Guide to Choosing the Right Design

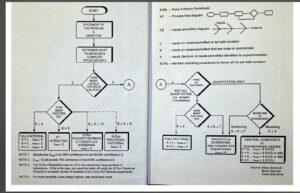

Fig 1: Guide to Choosing the Right Design

Selecting the right experimental design is a critical decision that can significantly impact the success of your research or project. Here’s a step-by-step guide to help you make an informed choice:

- Define Your Objectives

Begin by clearly defining the objectives of your experiment. What specific questions do you want to answer or what outcomes are you trying to achieve? Having well-defined objectives will guide your entire experimental design process.

- Identify Factors and Levels

List all the factors or variables that you believe may influence the outcomes of your experiment. Define the various levels or settings for each factor. This step ensures that you consider all relevant variables and their potential effects.

- Determine the Design Space

Establish the boundaries within which your experiment will operate. Define the minimum and maximum values for each factor, taking into account practical limitations and the desired scope of your investigation.

- Select the Experimental Design

Based on your objectives, the number of factors, and resource constraints, choose the most appropriate experimental design. Consider whether a full factorial, fractional factorial, Taguchi method, or RSM best suits your needs. Be sure to justify your choice based on your specific research goals and constraints.

Considerations for Special Cases

In some situations, your experiment may not fit neatly into standard experimental design categories. Here are considerations for special cases:

- Mixture Experiments

When you’re dealing with mixtures of ingredients or components, such as in chemistry or product formulation, specialised designs for mixture experiments are required. These designs account for the proportions of each component and their combined effects on the outcome.

- Nested Designs

In experiments with hierarchical structures or when factors have different levels of importance, nested designs may be appropriate. These designs allow for the exploration of variation at multiple levels, accommodating complex experimental setups.

- Blocking and Randomization

To control external influences or sources of variability that could affect your results, consider techniques like blocking and randomization. Blocking groups similar experimental units together to reduce variability, while randomization helps distribute the effects of uncontrolled factors evenly across experiments.

Evaluating and Validating Your Design

Before proceeding with your experiments, it’s essential to evaluate and validate your chosen design:

Pilot Testing

Conduct a small-scale pilot test of your experimental setup. This allows you to identify and address any potential issues, ensuring that your main experiments run smoothly and generate reliable data.

Statistical Analysis

Plan for appropriate statistical analyses that will enable you to extract meaningful insights from your data. Statistical tools like analysis of variance (ANOVA), regression analysis, and hypothesis testing will help you draw valid conclusions from your experiments.

The Role of Software in Experimental Design

Modern experimental design often relies on software tools to streamline the process and enhance efficiency. Here are some popular software options:

- Design of Experiments (DOE) software: Specialised software designed for planning, conducting, and analysing experiments.

- Statistical analysis software: Tools like R, JMP, and Minitab offer powerful statistical capabilities for experimental data analysis.

Practical Tips for Effective Experimental Design

Here are some practical tips to ensure your experimental design is effective:

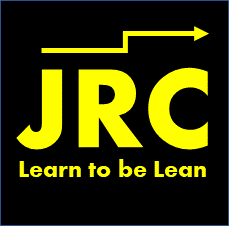

- Keep It Simple Statistically (KISS)

Fig 2: KISS Rule of Thumb

Complexity can lead to confusion and difficulties in data analysis. Start with a straightforward design and increase complexity only when necessary.

- Document Everything

Comprehensive documentation of your experimental setup, procedures, and results is crucial for reproducibility and future reference. Detailed records make it easier to troubleshoot and improve your experimental process.

- Learn from Previous Experiments

Review past experiments to identify patterns and insights. This knowledge can guide your current experimental design and help you avoid repeating mistakes.

In conclusion, the selection of the right experimental design is a critical determinant of the success of any research, product development, or process optimization endeavour. It ensures that experiments are conducted systematically, resources are used efficiently, and valuable insights are obtained.

Reference:

UNDERSTANDING INDUSTRIAL DESIGNED EXPERIMENTS (Ebook Only)

Authors: Stephen R. Schmidt and Robert G. Launsby (4th Edition) https://airacad.com/books/understanding-industrial-designed-experiments/

![UCOURSE.ORG [UCOURSE Academy] was established in Hong Kong in 2019 (company name: UCOURSE LTD), dedicated to providing high-quality online courses and courses for Chinese people in China, Hong Kong, and even all over the world. UCOURSE.ORG 【优思学院】于2019年成立于香港(公司名称:优思学院有限公司 / UCOURSE LTD),致力于为中国、香港、以至身处于全球各地的中国人提供优质的线上课程和考试认证,促进全国的人材培育、个人的职业发展,让学员在事业上事半功倍,同时助力国家的未来的急促发展。](https://ilssi.org/wp-content/uploads/2021/02/ucourse-logo-250.png)