Lean Process Improvement Made Simple: 5 Steps to Get Started

If you’re looking to improve the way work flows across your teams and deliver better results with fewer resources, Lean process improvement offers a practical framework to do just that. At its core, Lean is about identifying what adds value for your customers and removing the rest – waste, inefficiencies, bottlenecks, and delays.

But rather than diving deep into Lean theory, this guide focuses on the how – what you can actually do to improve your processes using Lean principles. Whether you’re managing projects in IT, operations, engineering, or any other business domain, these steps will help you move toward better outcomes with less friction.

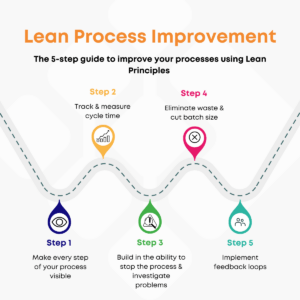

5 Lean Process Improvement Steps You Can’t Skip

Here’s a practical roadmap to begin improving your Lean process using accessible, incremental actions.

Step 1. See the Whole Picture: Visualize Your Workflow

Improvement starts with visibility. Without a clear picture of how work moves through your system, it’s difficult to know where the problems are.

Start by mapping your workflow on a visual board. This can be as simple as defining the stages a task moves through – from “To Do” to “Done.” But if you’re aiming for deeper insight, consider using value stream mapping. It breaks down your workflow into stages that reveal how value flows – and where delays or waste may occur.

In a dedicated Lean/Agile portfolio management tool such as Businessmap, you can create customizable work management boards and build value stream maps to represent your real-life process flow. This helps you uncover inefficiencies and identify improvement opportunities at every level of work.

With these capabilities in hand, it’s easier to pinpoint and analyze the value-added and non-value-added activities and turn your workflow into a source of continuous insight.

-

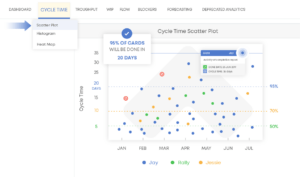

Track Cycle Time to Reveal What’s Slowing You Down

Once your workflow is visualized, the next step is to monitor how long work takes to move through it. This is where cycle time becomes a powerful indicator – the clock starts when work begins on a task and stops when it’s completed.

By tracking cycle time, you can identify stages where tasks get stuck or take longer than expected. These insights allow you to locate bottlenecks and optimize your delivery pace.

-

Don’t Push Problems Forward – Stop and Fix Them

Improving a process isn’t just about optimizing flow – it’s also about knowing when to stop and fix what’s broken. When a problem surfaces, it shouldn’t go unnoticed – or worse, get pushed downstream.

A fundamental Lean principle is enabling teams to stop the workflow when a problem is detected and then investigate it before proceeding. This idea is rooted in the principle of Jidoka – automation with a human touch. This principle encourages immediate response and team collaboration around issues, whether they’re delays, defects, or unclear priorities.

While originally applied in manufacturing, it’s just as relevant in knowledge work. Teams often use visual indicators such as blockers to highlight problematic work items.

-

Cut the Waste and Reduce Workload Size

Waste can take many forms – overproduction, delays, rework, and more. A practical first step toward eliminating it is to reduce the size and quantity of work in progress. Lean recommends working in smaller batches, matching output with demand, and delivering just in time.

A good place to start is by limiting work in progress (WIP). The fewer things you try to do at once, the more focus and flow your team will have. You can also split large chunks of work into smaller, manageable items and level the demand across your team. This is aligned with Lean principles like Just-In-Time and Heijunka (production leveling).

5. Create a Feedback Loop

Improvement doesn’t happen in a single pass. You need regular check-ins to understand what’s working and what’s not. Set a cadence for reviewing process metrics, team input, and customer feedback.

This could take the form of retrospectives, stand-ups, or recurring process reviews. The goal is to adjust based on real-world results – not just theory.

One Last Thing to Remember

Improving a Lean process is less about one-time optimization and more about building a system that evolves. With visibility, performance measurement, collaborative problem-solving, and regular feedback, your process becomes a living system that improves with every cycle.

Lean principles give you the foundation. The right tools help you put them into practice.

About the author:

Nikolay is a strategic marketing leader and subject matter expert at Businessmap, specializing in OKRs, strategy execution, and Lean management. Passionate about continuous improvement, he has authored numerous resources on modern-day management. As a certified PMI practitioner and SAFe Agilist, Nikolay frequently shares his insights at Lean/Agile conferences and management forums.

![UCOURSE.ORG [UCOURSE Academy] was established in Hong Kong in 2019 (company name: UCOURSE LTD), dedicated to providing high-quality online courses and courses for Chinese people in China, Hong Kong, and even all over the world. UCOURSE.ORG 【优思学院】于2019年成立于香港(公司名称:优思学院有限公司 / UCOURSE LTD),致力于为中国、香港、以至身处于全球各地的中国人提供优质的线上课程和考试认证,促进全国的人材培育、个人的职业发展,让学员在事业上事半功倍,同时助力国家的未来的急促发展。](https://ilssi.org/wp-content/uploads/2021/02/ucourse-logo-250.png)