Industry 4.0: Integrating IoT, Robotics, and Human-Machine Interfaces

Throughout history, industrial revolutions have significantly shaped how we live and work. Starting from the steam-powered first industrial revolution, we’ve seen a series of transformations leading us to the current era, known as Industry 4.0.

This phase is characterized by the integration of technologies like the Internet of Things (IoT), robotics, and cyber-human interfaces into industrial operations, making them more interconnected and intelligent.

A key discussion in this context, as brought forth by Professor Peter Hines, revolves around the role of Artificial Intelligence (AI) in Industry 4.0 and the anticipation of Industry 5.0, where AI’s maturity could redefine industrial landscapes once again.

Understanding Industry 4.0: Components and Challenges

Industry 4.0 is a leap into digital transformation. It incorporates IoT, allowing machines to communicate and make decisions based on real-time data. It consists of advanced robotics work alongside humans, not just as tools but as collaborators.

In this regard, big data analytics offer deep insights into operations, optimizing efficiency. Another critical aspect is cyber-physical systems that merge physical operations with computer-based algorithms, enhancing automation and monitoring.

However, integrating these technologies presents significant challenges. First is the complexity of merging diverse systems and technologies into a cohesive, functioning whole. Then there are security concerns, as interconnected systems increase the risk of cyber-attacks. Perhaps the most significant challenge is the current limitations of AI. While AI offers immense potential, its practical application in Industry 4.0 is not without hurdles.

Professor Peter Hines argues that AI, as it stands, isn’t mature enough to reap practical benefits for Industry 4.0. He points out that while AI has made strides, its application in complex industrial environments is still evolving. There are issues regarding AI’s decision-making capabilities, adaptability, and understanding of nuanced industrial processes.

The Evolution and Future of AI in Industry 4.0

Currently, AI in Industry 4.0 primarily focuses on data analysis, predictive maintenance, and some level of automation. It’s impressive but limited. AI systems can analyze patterns and predict equipment failures, but they struggle with complex decision-making and problem-solving that require a deep understanding of the industry.

These shortcomings become evident in scenarios requiring nuanced judgment or creative problem-solving – areas where human expertise still reigns supreme. AI’s limitation in contextual understanding and adaptability in unpredictable situations is a gap in its current application within Industry 4.0.

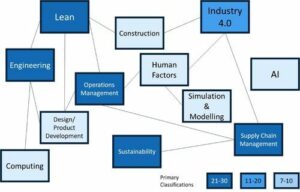

Lean Industry 4.0: Past, present, and future by Professor Peter Hines et al., 2020

The future of AI in Industry 4.0 looks toward not just analyzing data but making intelligent decisions based on it. Advancements in machine learning and neural networks could lead AI to understand complex industrial processes more deeply, adapt to changing conditions, and even anticipate needs, leading to more autonomous and efficient industrial operations.

Envisioning Industry 5.0: AI’s Transformational Role

Industry 5.0 is envisioned as the next evolutionary step, where AI’s capabilities extend beyond automation and data analysis to include advanced decision-making and creativity. It’s a shift from machines just doing tasks to machines thinking and innovating.

In Industry 5.0, AI is expected to possess not only the ability to analyze vast amounts of data but also to derive creative solutions, make autonomous decisions, and learn from interactions in a way that mimics human intelligence more closely.

This level of AI maturity could transform industries. Machines could design processes, optimize production autonomously, and even innovate new products or solutions, marking a significant shift in how industries operate and compete.

Comparative Analysis: Industry 4.0 vs. 5.0

While Industry 4.0 focuses on digital interconnectivity and data-driven decision-making, Industry 5.0 is anticipated to take this further by imbuing machines with a higher level of intelligence and creativity. The distinction lies in the depth of AI integration and the level of autonomy and innovation it brings.

The shift from Industry 4.0 to 5.0 is expected to be marked by even greater collaboration between humans and machines, with AI playing a more central role in decision-making processes. This could lead to more personalized and efficient production methods and potentially reshape industrial job roles.

The transition will have profound implications for various industries, potentially leading to increased productivity and innovation. However, it also raises questions about workforce dynamics, the need for new skills, and the potential displacement of traditional jobs.

Ethical and Societal Considerations

The advancement of AI in Industry 5.0 brings ethical considerations to the forefront. Issues like decision-making transparency, privacy, and the moral implications of AI-driven creativity are critical to address.

The societal impact of such a technological leap could be significant, affecting employment patterns, requiring new educational focuses, and potentially widening the gap between technologically advanced and lagging regions.

Balancing Progress and Responsibility

Industries and policymakers must balance technological progress with ethical and social responsibility. This involves ensuring equitable access to the benefits of these technologies and mitigating potential negative impacts on society.

Conclusion

In summary, the evolution from Industry 4.0 to Industry 5.0, centered around the maturity and integration of AI, presents a fascinating and complex landscape. While Industry 4.0 has set the stage for interconnected and intelligent industrial operations, the potential leap to Industry 5.0, as envisioned by Professor Peter Hines and others, could redefine these operations at an even more fundamental level. Balancing technological advancements with practical implementation, ethical considerations, and societal impacts will be crucial in navigating this exciting yet challenging transition.

![UCOURSE.ORG [UCOURSE Academy] was established in Hong Kong in 2019 (company name: UCOURSE LTD), dedicated to providing high-quality online courses and courses for Chinese people in China, Hong Kong, and even all over the world. UCOURSE.ORG 【优思学院】于2019年成立于香港(公司名称:优思学院有限公司 / UCOURSE LTD),致力于为中国、香港、以至身处于全球各地的中国人提供优质的线上课程和考试认证,促进全国的人材培育、个人的职业发展,让学员在事业上事半功倍,同时助力国家的未来的急促发展。](https://ilssi.org/wp-content/uploads/2021/02/ucourse-logo-250.png)